DUSTEX®

WATER DISPERSION & SPRAYING SYSTEM

The Dustex water dispersion system has been developed to provide a cheap and effective weapon against dust laden air, helping maintain a clean and safe working atmosphere.

DUSTEX® – for a dust free environment

At many installations it is often necessary to stop or limit production, even encapsulate certain areas, to enable air cleaning to be carried out – otherwise it is dangerous for the employees, or aggressive to the environment and surrounding areas. The criteria of permitted values of dust are getting more and more severe. A right for clean air is developing.

With all these factors in mind, the DUSTEX® system has been developed to supply a cheap and effective weapon against dust laden air.

Plant without Dustex

Advantages of DUSTEX®

► Low consumption of water and compressed air

► The addition of only 1 litre per ton material

► Little mounting expenses

► Robust, universal and easy to maintain system parts

► Anti-freezing device against disturbances in low temperature operation

► Self cleaning of the nozzles by ultra sonic effect

Plant with Dustex

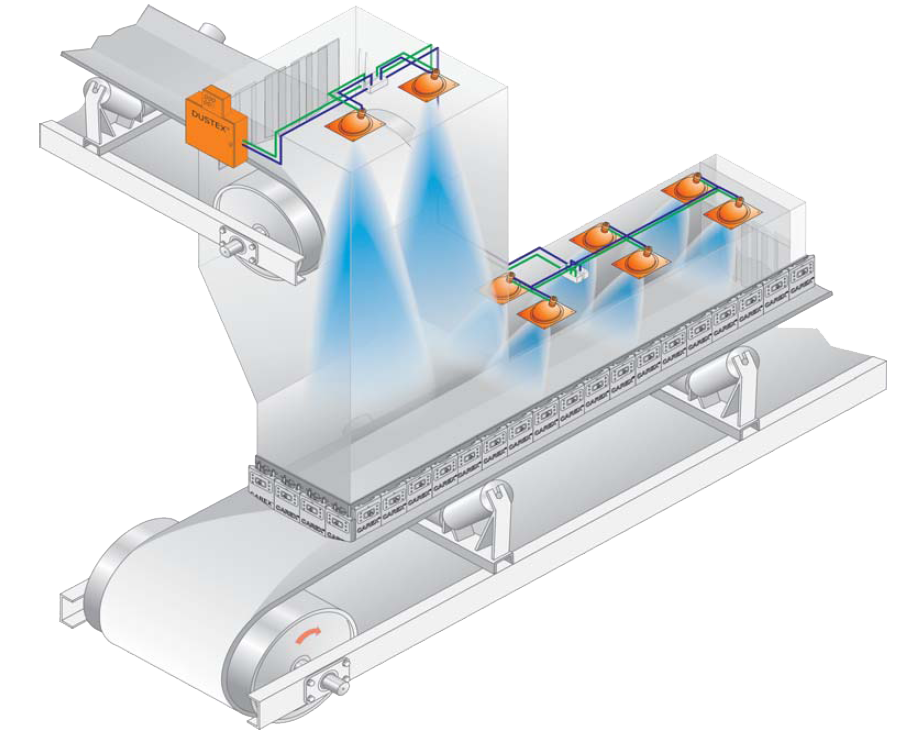

DUSTEX® Water Dispersion Systems

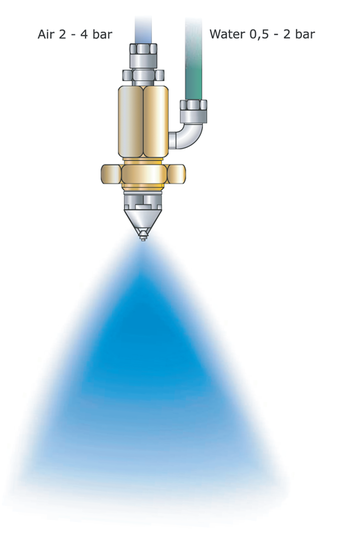

These systems work with two material nozzles at low pressures with the media water and compress air.

Water is split up in micro-fine drops (10 – 50 µm) by air pressure in an ultrasonic field. Thus, a maximum drop quantity and drop surface is gained out of the sprayed water.

They are particularly suitable when:

- very low emission values have to be observed

- the water consumption should remain low

- the humidity addition is not allowed to exceed the thousands limit

- the product is thermally treated later on

DUSTEX® Dispersion Nozzle

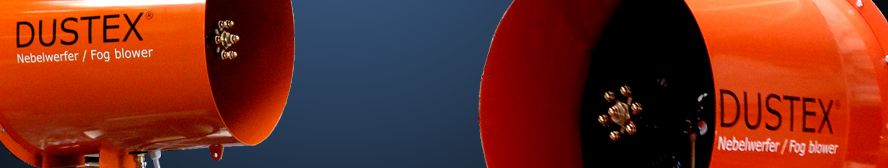

DUSTEX® Water Spraying Systems

These systems work with one material nozzles, only with the medium water.

They produce fine up to micro-fine drops with pressure of 4-10 bar.

They are particularly suitable when:

- low emission values have to be realised

- a slightly higher water consumption is not a problem

- a higher humidity in the product is not a problem, or is even requested in some circumstances

- a plant cannot or can hardly be encapsulated

- the product has to be loaded and unloaded several times

DUSTEX® Water Nozzle

Materials and Fields of Application

The following materials are particularly well suited for the DUSTEX treatment: coal, coal dust, ore, waste moulding sand, gravel, sand, lime and crushed stone, fly ash, chemical products, alum earth, fertilizer, agricultural products, domestic waste.

Fields of application:

► Installations for material treatment by crushers, sieves, blenders, classifiers and conveyor belt transfers

► Installations for feeding material: filling of stock piles and tip bunkers, ship loading by telescope chutes, vehicle loading from silos

► Silos, stock houses, material depots, workshops, where dust has to be quickly removed for inspection or other operations

► Installations for removal of material by drilling, milling and sand blasting

► Danger of combustion/fire, dust explosion zones, removal of the critical conditions for the starting and spreading of fires and explosions

► Chemical and biological processes, atomizing of aerosols for gas cleaning and gas reaction or for removal of odours