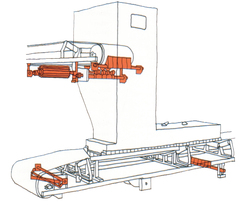

DIRTEX®

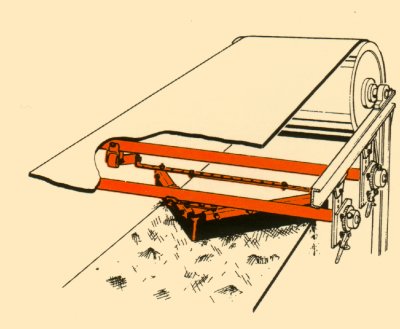

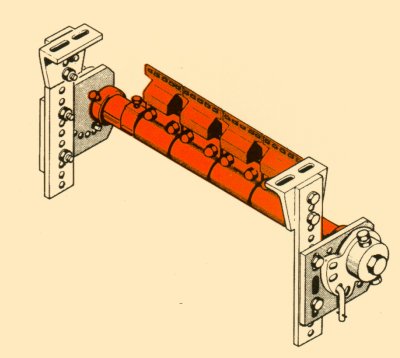

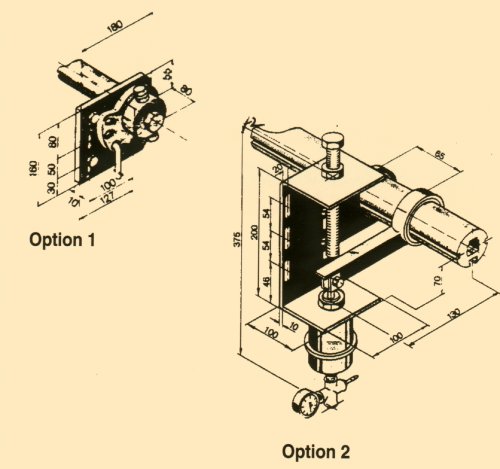

CONVEYOR BELT CLEANERS

Linemann has developed a range of conveyor belt cleaners designed to prevent the build up of even the most abrasive materials, ensuring their uninterrupted movement, maximising efficiency and maintaining production.

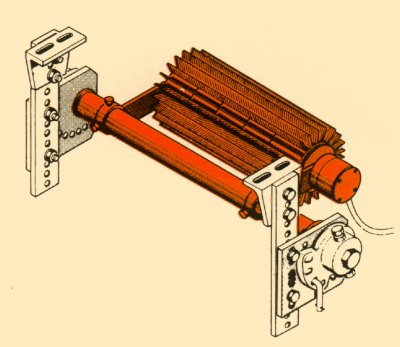

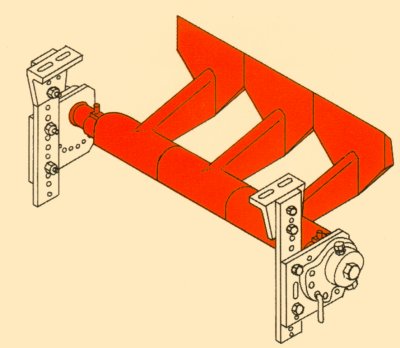

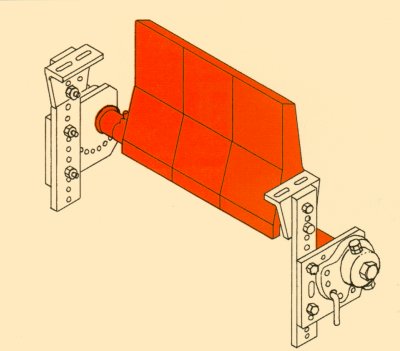

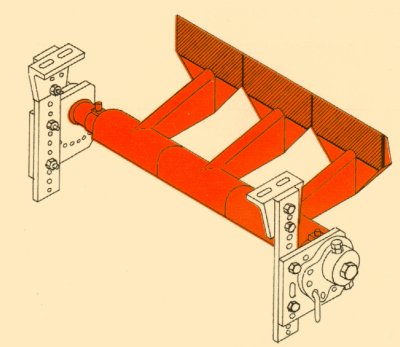

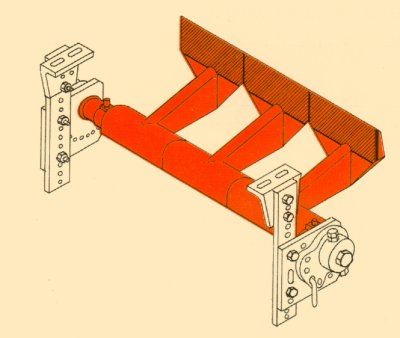

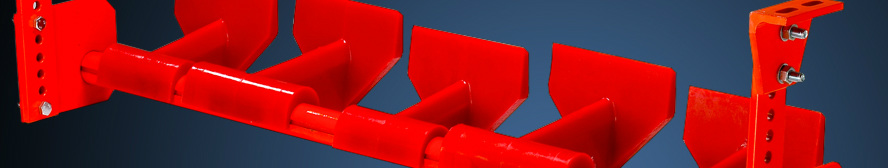

The various scrapers and belt cleaning brushes are all interchangeable, literally clipping on to a common axle, enabling the system to be adapted to suit every application and designer preference.