LINEX®

CONVEYOR BELT CENTRALISER

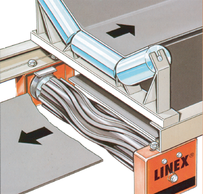

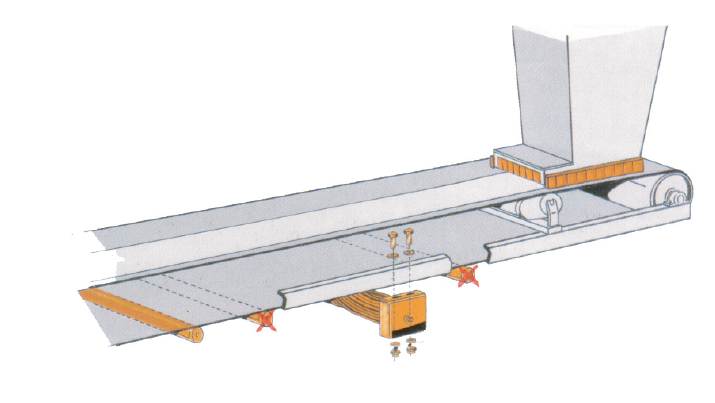

Linex® conveyor belt centralising idlers ensure symmetrical belt running and protect the belt edges. They help to prevent expensive production breakdowns, and are maintenance free, wear resistant and easy to install.

Linex® centralising idlers can be applied to conveyor belts used in lignite and coal mining, power plants, cement works, gravel, stone and sand quarries, foundries, aluminium works, steel works, port loading facilities, chemical plant, water and sewage works, refuse incineration plants, and in the wood and metal industry.

Applications

- ensure symmetrical belt running and protect the belt edges

- help to prevent expensive production breakdowns

- maintenance free, wear resistant and easy to install

- can be applied to conveyor belts used in lignate and coal mining, power plants, cement works, gravel, stone and sand quarries, foundries, aluminium works, steel works, port loading facilities, chemical plants, water and sewage works, refuse incineration plants, and in the wood and metal processing industry.

Linex® should be fitted as original equipment to all conveyor belts in order to eliminate tracking fault due to:

- uneven, worn or wrongly spliced conveyor belts

- incorrect idler adjustments

- conical head pulleys

- distorted steel structure

- differential structure temperatures

- asymmetrical or transverse shear-producting load

- asymmetrical friction forces caused by pulleys, idlers, scrapers and chute seals

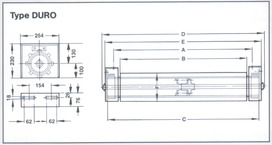

Specification

| TYPE DURO | Belt Width A | A mm | B mm | C mm | D mm | E mm | F** mm | Weight Kg |

|---|---|---|---|---|---|---|---|---|

| LID 50 | 500 | 740* | 650 | 810 | 880 | 840 | 190.5 | 47 |

| LID 65 | 650 | 890* | 800 | 960 | 1030 | 990 | 190.5 | 47 |

| LID 80 | 800 | 1090* | 1000 | 1160 | 1230 | 1190 | 190.5 | 53 |

| LID 100 | 1000 | 1280* | 1190 | 1350 | 1420 | 1380 | 190.5 | 58 |

| LID 120 | 1200 | 1530* | 1440 | 1600 | 1670 | 1630 | 190.5 | 63 |

| LID 140 | 1400 | 1720* | 1630 | 1790 | 1860 | 1820 | 190.5 | 70 |

| LID 160 | 1600 | 1950* | 1860 | 2020 | 2090 | 2050 | 190.5 | 75 |

All specifications are correct at time of of going to press and are subject to change without prior notice.

* Can be fitted for standard supporting frames. Other dimensions on request.

** Neopren-standard diameter 59mm

** Polyurethane food qualified diameter 69mm

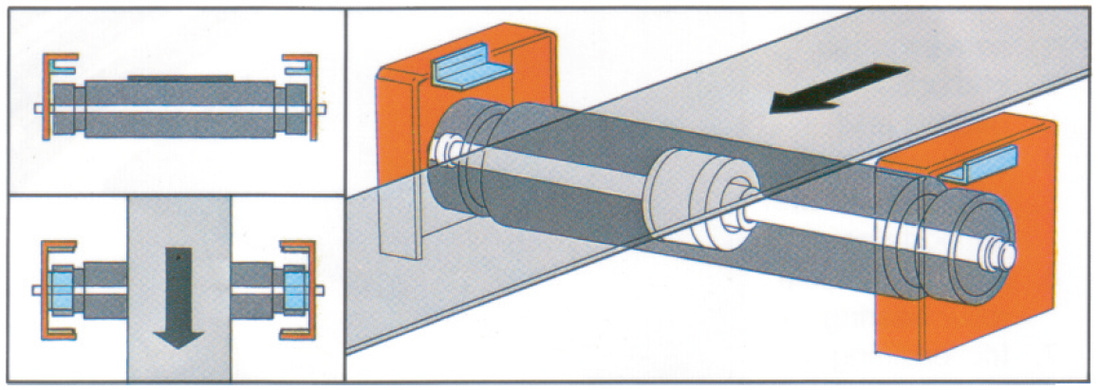

Central Spherical Roller Bearing

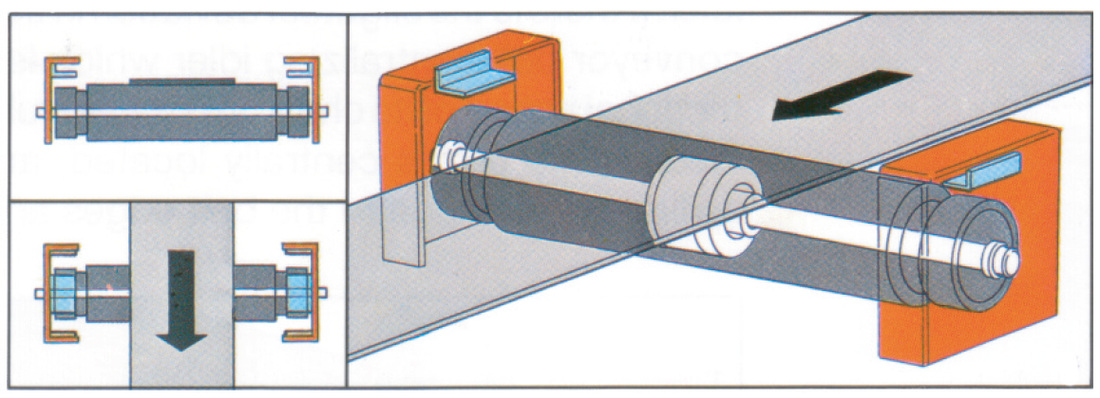

Ideal Running

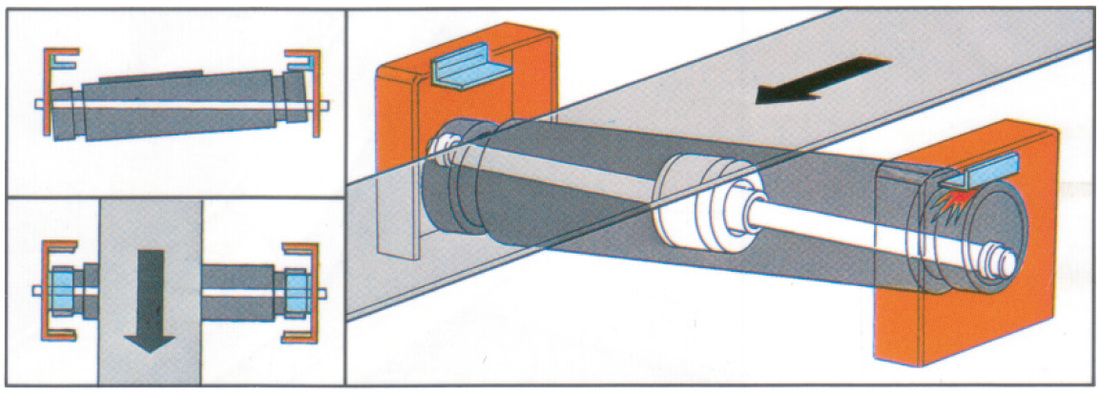

Tilting

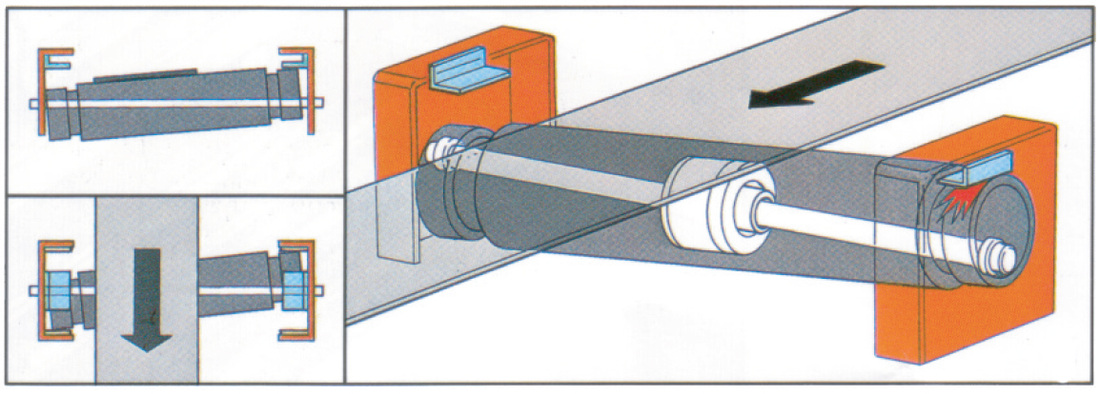

Twisting and Correction

Ideal Running

IMPORTANT NOTE

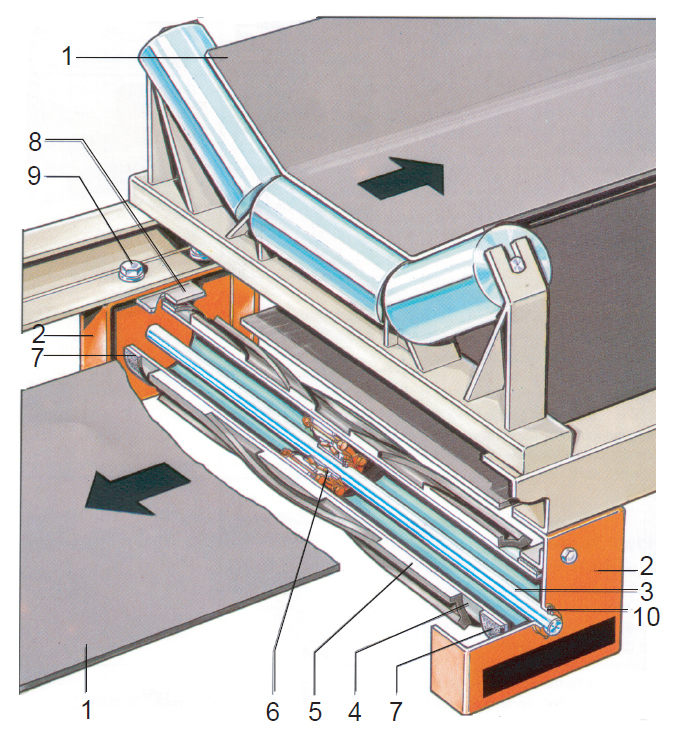

The corrective effect of the Linex® is achieved by the weight of the conveyor belt and not by its tension. The Linex® must not be used as a snub pulley.

Linex® conveyor belt centralising idlers have been designed according to the physical laws of gravity and friction – and on the basis of many years experience with conveyor belts in practical use.

Linex® ensures true and in-line running of the conveyor belt. It is usually installed just before the tail pulley, virtually beneath the material transfer chute, in place of a support idler. If there is the slightest deviation in the running of the belt, the Linex® centralising idler will re-align the belt to it’s central position. This ensures that the load on the belt is centrally located, and reliably prevents any slide spillage or damage to the belt edges and the skirting of the chute.

|

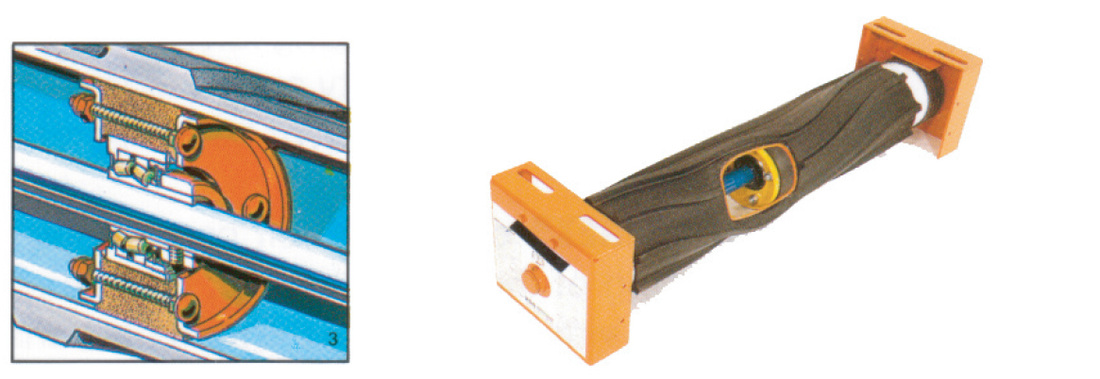

1. Conveyor belt

2. End brackets 3. Bearing axle 4. Steel roller body 5. Rubber cover with support ribs |

6. Spherical double roller bearing

7. Friction lining 8. Braking angle 9. Bolted connection 10. Clamping pin |